https://blog.naver.com/ktdong61/221764619147

Marlin 2.0.1 펌웨어 올리기(SKR V1.4)

프린터 사양(Ultimaker2 extended clone) - 보드 : Bigtree SKR V1.4 - 모터 드라이브 :TMC 2209 ...

blog.naver.com

프린터 사양(Ultimaker2 extended clone)

- 보드 : Bigtree SKR V1.4

- 모터 드라이브 :TMC 2209 4개(X,Y,Z,E)

- LCD : REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER

- 파워 : 24V

* 기존 12V 전원을 24V로 변경하여 쿨링 팬 및 히터를 24V용으로 교체, 챔버에 설치한 LED는 12V로 사용

- extruder : 1개

- 베드 레벨링 : 수동

- 출력물 사이즈 : 240(X)*210(Y)*298(Z)

- Endstop : Stallguard2

- 핫엔드 Led : 5V Neo Pixel Led

- Case Led : 12V Led strip

- 팬 (5) : 파트, 익스트루더 , 보드, 파워 (24V)

open project로 다운 받은 펌웨어를 로드한 다음 configuration.h 와 configuration_adv.h를 수정한다.

< configuration.h >

serial port는 0 으로 둔다. -1 로 변경시 WiFi 모듈이 인식되지 않는다.

제품 매뉴얼에 따라 115200 으로 변경

marlin/src/core/boards.h 에서 LPC1768 보드중 이름을 복사하여 붙여 넣기

* 최신 펌웨어(2.0.6)에서는 보드이름이 BOARD_BIGTREE_SKR_V1_4(2.0.1펌웨어) 에서 BOARD_BTT_SKR_V1_4 로 변경되었다.

필라멘트 직경을 1.75로 변경

히트베드가 설치되어 있으므로 1로 변경

히터 최고온도 조정

기존 PID 값으로 변경

기존 PID 값으로 조정

엔드스톱 위치 설정

스테퍼 드라이브 설정

기존 값 입력

엔코더 방향 변경

LCD 창에서 한글메뉴를 사용하려면 en ---> ko_KR 로 변경하면 되는데 글꼴이 예쁘지 않다.

한글화가 안된 메뉴는 src/lcd/language_ko_KR.h 에서 추가하면 될 듯

LCD 타입 입력

핫엔드에 설치할 LED 설정

< Configuration_adv.h >

파일 이름이 길어서 LCD화면에 짤릴 경우 파일 이름이 스크롤 된다.

stallguard2 설정

전원을 24V를 사용할 경우 24V 로 변경

TMC 드라이버 모니터링

핀 설정 상태 모니터링

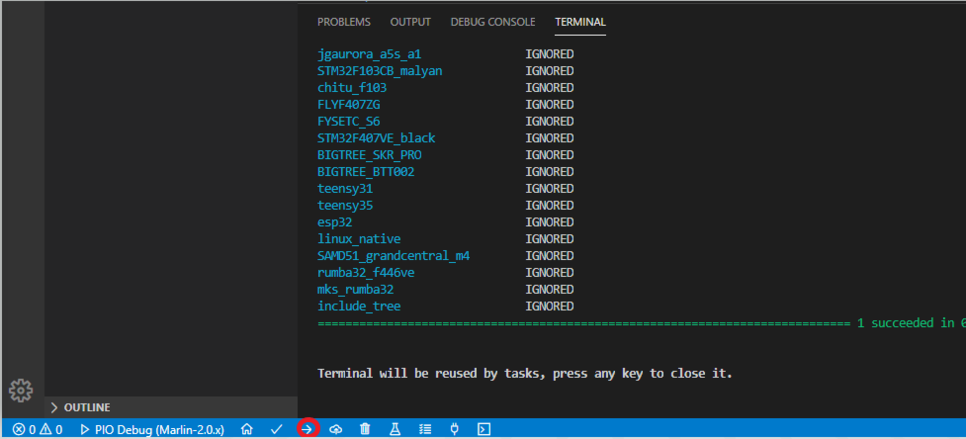

visual studio code 하단부에 있는 Build 버튼을 클릭하여 컴파일을 한다.

컴파일이 성공적으로 완료되어도 problems 에 건수가 표시되면

해당 라이브러리를 검색하여 설치한 후 다시 컴파일 한다.

에러없이 컴파일이 완료되면 하단부에 있는 업로드 버튼을 클릭하여 보드의 SD카드로 업로드 한다.

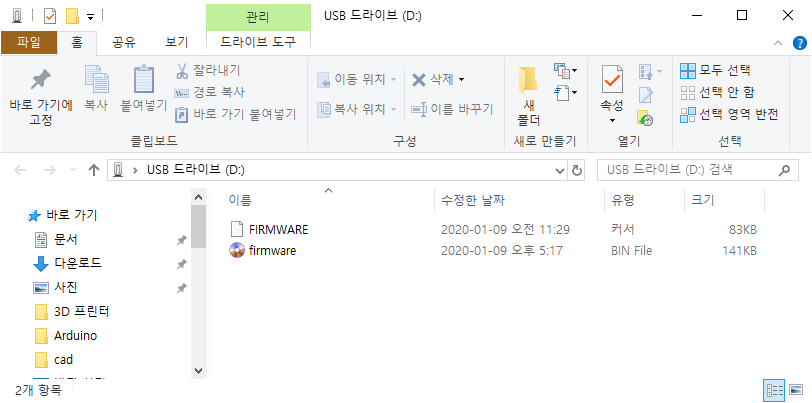

SD 카드에 컴파일 완료된 firmware 가 업로드 되어 있음을 확인할 수 있다.

보드의 reset 버튼을 누르면 firmware.bin 이 FIRMWARE.CUR 로 변경되면서 펌업이 완료된다.

'3D프린팅' 카테고리의 다른 글

| The Best Ender 3, V2, & Pro Cura Profile / Settings (0) | 2022.05.26 |

|---|---|

| ENDER3 E3D V6 핫엔드 + 타이탄 익스트루더 다이렉트 적용 (0) | 2022.05.26 |

| marlin _bootscreen 설정 방법 (0) | 2022.05.26 |

| RTTTL Ringtone Downloads (0) | 2022.05.26 |

| Configuring Marlin (0) | 2022.05.26 |

댓글